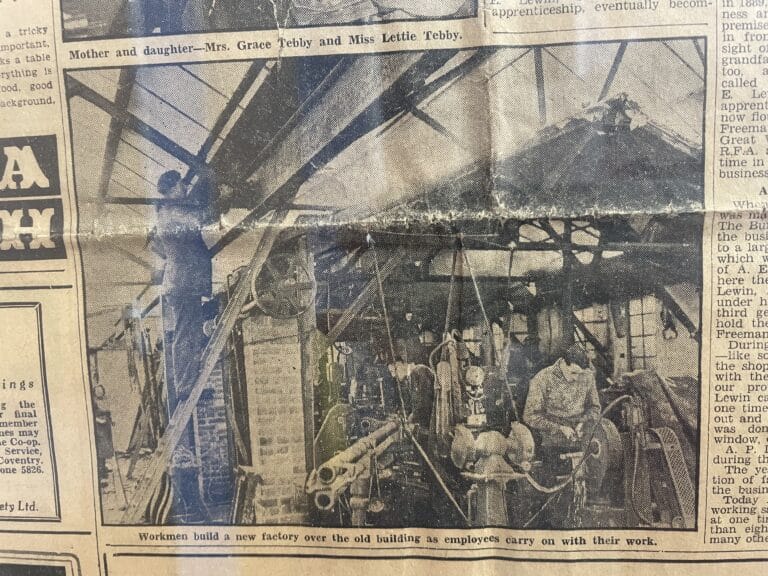

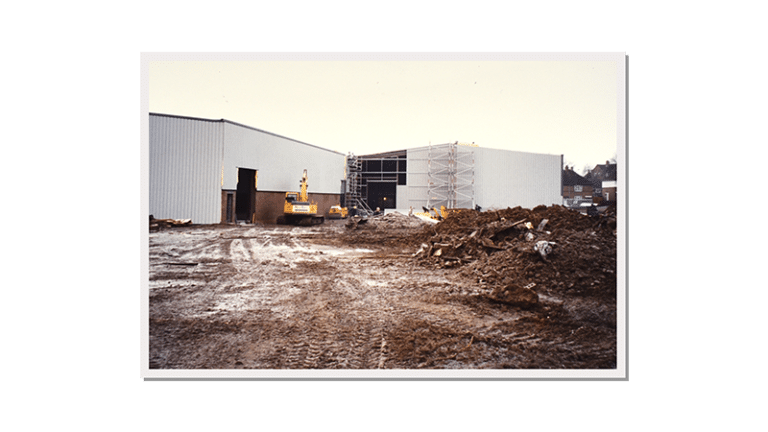

We remember when…

We let the fire brigade run exercises at our empty site on Farmers Ward Road in 1996 (we’d moved to our current site, Millers Road, by then). Little did we know that it would lead to rumours of insurance fraud. We thought we were doing a good deed, supporting the local fire brigade. Instead, we found ourselves making headlines in the local paper!