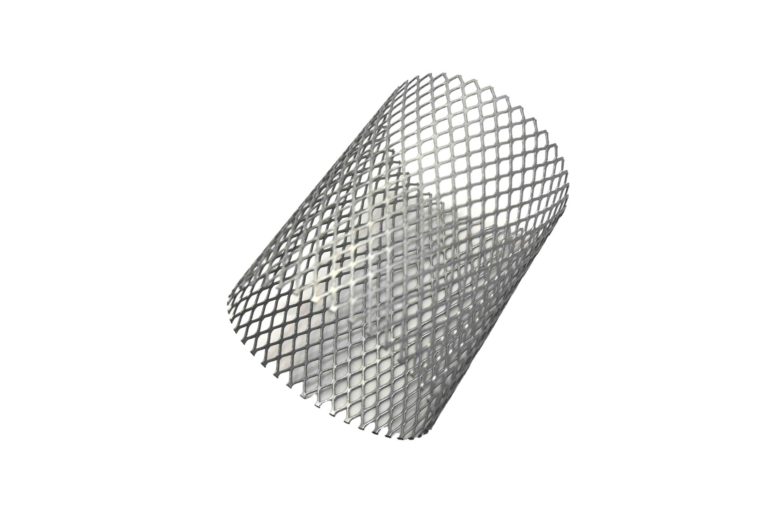

An expanded metal tube is a cylindrical structure made from a sheet of metal that has been cut and stretched to form a mesh-like pattern of interconnected strands. This process creates a tube with a diamond or hexagonal pattern of openings, which gives it the unique characteristic of a high strength-to-weight ratio.

We stock a wide range of materials in a variety of sizes helping us to deliver on time and in budget. This wide-ranging stock combined with our extensive product design knowledge allow us to offer a low-cost or no-cost tooling solution for new products. We don’t charge for holding free issue products for ‘just in time’ projects.

Our components can be bespoke, custom-made, automated or handcrafted. Whatever your need for expanded metal tubes, our precision manufacturing ensures top-quality, durable parts that meet your exact specifications.

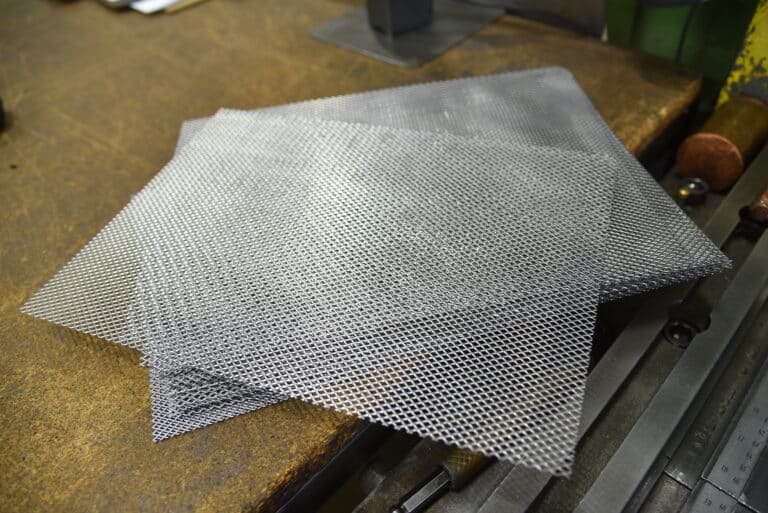

Each expanded metal tube starts out as a sheet blank

Cut to size using various cutting machines and guillotine

If you want to know more about our bespoke prototyping service and capabilities or have a question about how our perforated products are made, please get in touch with our expert team. We'll discuss your requirements and explain how our skilled engineers work with you to provide the perfect solution.